What Assurance and Challenges Do Vintage IPC Test Methods such as ROSE pose for New Technology?

The word “Vintage” says it all, it is old, it is antique, it is a curiosity in the modern world.

The ROSE test was conceived over 50 years ago, and it was envisaged as a process control tool. The inventors never intended the ROSE test to be used as a cleanliness test. Following the introduction of the technique an effort was taken to hijack this test from its original purpose and turn it into a cleanliness test, incorporating the method into IPC-TM-650 method 2.3.25.

In this committee process there was a successful effort to make this into a cleanliness test, i.e. there was a strong desire from certain quarters to create a pass/fail number. Hence, way back then the question “How Clean is Clean or How Clean is Good? was first formulated. This was a good question, but there are no verifiable answers.

In the ROSE test the total soluble ionic species from the surface of a PCA are detected. The test measures, anions, and cations, and these can be non-organic or organic. The detection of all these ions is done simultaneously and in 15 minutes. No other technique can do this. A generic name for this equipment is solvent extraction conductivity (SEC) measurement apparatus.

SEC measures conductivity, but typically the results are expressed in µg/cm² of NaCl. Hence, this answer is converting whatever ions constituted to the ion flow in the conductivity cell are converted into an equivalent weight of NaCl that corresponds to that current flow.

An important assumption from the results of a SEC test is that the salt is distributed evenly over the whole area of the PCA. This is expedient and makes sense from a practical point of view, but it is very unlikely that the residues are distributed evenly across the PCA. Based on the technology at the time, i.e. the components and fluxes, a value of 10µg/sq.inch was chosen as a suitable pass/fail value based on typical contemporary measurements. This value is now fully metric and is the familiar 1.56µg/cm².

When this test was first formulated the deficiencies of this approach were recognised, as the component density was not truly taken into account, and neither was the flux loading or activity. Furthermore, the measured value was an average from the whole board. This averaging is recognised as being inappropriate as the flux residues are most likely to be at entrapment sites. A secondary issue with localisation of flux residues is that where the thermal load is high on the PCA, the amount of unreacted flux residues will tend to be higher, and therefore more problematic.

Spin forward to today, component configurations and sizes are very different, as are the flux chemistries. The 1.56 value has never been updated to take account of these wide ranging technology changes, and hence the 1.56 has very little relevance today.

There has long been a wish to return to the original concept, that the SEC test be used as a process tool. Hence, using the SEC test in a process monitoring mode the test result for a specific PCA is compared to a library value. The library value is determined by an OE (Objective Evidence) exercise. There is no universal single value for the gigantic plethora of PCA types. The OE approach is now part of the latest version IPC-J-Std-001.

While the SEC manufacturers and standards writers understand this new approach there is huge inertia in the industry to drop the cleanliness test and the 1.56µg/cm². However, within the latest versions of IPC-J-Std-001 the 1.56µg/cm² has now been dropped. This came about as high volume OEMs with complex high density PCA are making high reliability products, but these same products do not comply with the 1.56µg/cm² pass/fail criterion. This state of affairs is quite ridiculous. The ensuing discussion around “How Clean is Clean” or “How Clean is Good for it to be Reliable”, were unanswerable, and hence following lengthy discussions the 1.56 cleanliness standard was dropped.

What is in a name? The latest revision to IPC 2.3.25 ROSE method is still in progress after 8 years, and the 2012 version is still current. The call out of the 1.56µg/cm² value from IPC-J-Std-001 is no longer current. The technology and the landscape for the ROSE test has changed and an update is urgently needed. The continued desire to continue to use the extant test leads to confusion. In IEC the method based on testing with SEC now uses the name “Process Ionic Contamination Testing”, or PICT. Importantly this method was based and substantiated by a Gage R&R exercise, which proved the PICT method was compliant with Gage R&R requirements. This Gage R&R study was undertaken with a closed loop system from GEN3, and was undertaken by multiple sites from around the world. In this IEC standard this method adopts the approach that a measurement for a specific PCA is compared to a library value, and is in line with the IPC approach of using Objective Evidence. Using the objective evidence approach and SEC results, standard SPC methods can easily applied, such as trend analysis. Furthermore, the SEC tool can be readily incorporated into an Industry 4.0 setup.

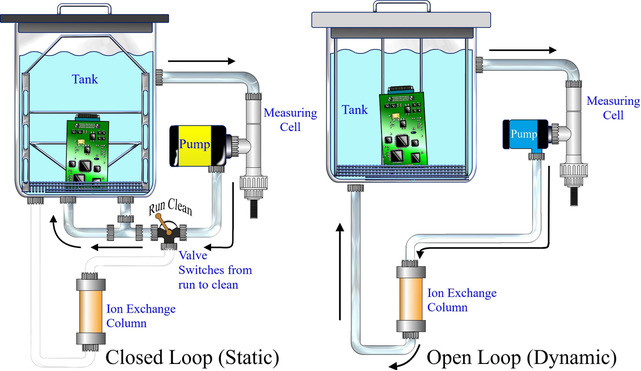

Within the current IPC standard there are three listed methods, Open loop, Closed loop and a manual method. There is no verification of the manual method and any attempt to provide Gage R&R would be very problematic, and hence it’s not recognised in main-stream manufacturing. Open and Closed loop have been known as Dynamic and Static methods, but this nomenclature is confusing and is being dropped.

In both the Open and Closed loop, the solution circulates through a tank into which the PCA is inserted for testing. The open and closed naming refers as to whether the deionising column is included in the circulation system during a test. In the open system the circulation includes the deionising column, and with the closed system the deionising column is not part of the test circuit.

A clear difference then is that the volume is reduced for the closed system, and the lower the volume the more sensitive is the instrument. A second important difference is that in the open system the total content of ionic residues is arrived at by integration of the electrical signal from the conductivity cell. For the closed system the final conductivity value is simply taken. Another issue with the Open loop system is that the effect of CO₂ is not apparent, whereas with the Closed loop the effect of CO₂ or any other gas pollutant is easily seen and corrected for. Hence the Open Loop technique does not correct for CO₂ or other gases. The Open Loop is always striving to measure near the detection limit, and hence signal noise is more of an issue. The Open Loop is continually cleaning the solution, so the propensity for dissolution of residual ions is always being maintained at its maximum, and hence inadvertent leaching of ions from the various resin matrices in a PCA is a potential problem. This new concept of using SEC technique as a process control tool has been fully demonstrated by Robert Bosch in Germany. They undertook a global internal intercomparison where they demonstrated that they could achieve a 6 sigma process globally. This validation was based on measurements with a GEN3 Contaminometer (CM Series). This project was reported at the IPC Apex conference in 2017 in San Diego.

So to answer the question “What Assurance and Challenges Do Vintage IPC Test Methods Such as ROSE pose for New Technology?”, the answer becomes apparent. The current ROSE test is long overdue for a needed update. The requirements document IPC-J-Std-001, has moved on and now uses the SEC as part of a process control tool. The need to be aware of component density and mix, solders, fluxes and coatings etc, is now a moot point, since all PCA have their own unique reference value, which can be any number, 1 or 1.56, or 3.93, etc. etc. This unique reference number for each PCA is generated by an Objective Evidence study as outlined in the latest version of IPC-J-Std-001. To date only the closed loop system has been proven to achieve Gage R&R.

Is a ROSE still a ROSE when it's PICT?

Author - Chris Hunt, CTO, GEN3

Date - Tuesday 18 February 2025

Copywrite ©