AutoCHT

The AutoCHT is a precision tool developed to simulate and control localised condensation on electronic test boards during Damp Heat Testing (DHT). It works by adjusting the temperature of the test board independently of the chamber's environment—adjust test board temperature precisely to 0.1°C control, to at least 1˚C below the Dew Point.

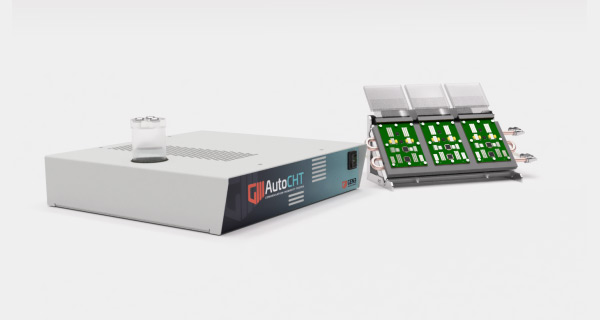

Paired with the AutoSIR2+, the tester enables real-time monitoring of how moisture affects different board designs, spacings, and coatings—giving you unrivalled insight into moisture-driven failures.

- Generates controlled condensation on test boards

- Works independently from DHT environmental settings

- Fully integrated with the GEN3 AutoSIR2+

- Realistic simulation of harsh environmental effects

- Ideal for testing coating integrity, spacing, and component layout

- Logs all test and temperature data for future analysis

- Customisable temperature cycles and profiles

- Connection via AutoSIR2+ passthrough cabling

- Single software controls both AutoSIR2+ and AutoCHT *Must be used in conjunction with the AutoSIR2+

- Visual tracking of target vs. actual temperature

- Retrofittable into existing DHT chambers

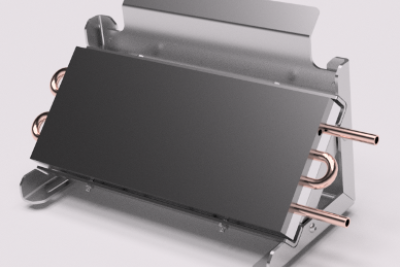

- Platen-mounted system holds up to 3 test boards at a 45° angle

- Platen Temperature range: 36°C to 43°C

- Adjust test board temperature with a step size of 0.1°C, to at least 1˚C below the Dew Point

- DHC Requirements Nominal 40°C / 90% RH

- Operating environment of 18°C - 26°C

- Magnetic coupon mounting system

Standard DHT alone doesn't always trigger real-world failure mechanisms. The AutoCHT introduces controlled surface-level moisture (condensation), dramatically increasing the sensitivity of your tests—often revealing coating or material flaws within hours.

Yes. The AutoCHT is the ideal tool for characterising Electrochemical Migration (ECM) failures due to poor conformal coating coverage. The latest research points to the need to form a continuous water film for dendritic growth to occur. Such a water film should never occur in Damp Heat Chamber (DHC) where the climatic condition prevents condensation, and hence dendritic failure is rarely seen. With condensing conditions and exposed electrified terminations due to coating failures can lead to dendritic growth in very short time scales. This makes the AutoCHT the ideal tool to characterise conformal coatings and their coverage.

Yes. The Condensation Tester is retrofittable into most standard DHT chambers (nominal 40°C / 90% RH). No special chamber modifications are usually required, however we would recommend discussing your application with a GEN3 Technical Specialist to confirm.

The system accommodates up to 3 test boards, with 16 channels each, mounted at a 45° angle using coated magnetic holders.

No. The AutoCHT uses an advanced AutoSIR2+ App, which means you do require an AutoSIR2+ to run the AutoCHT. This allows the user to control both systems, configure temperature profiles, and monitor results from one application.

- Detection of conformal coating failures

- Evaluation of layout spacing impacts

- Investigation of moisture-induced dendritic growth

- Environmental reliability assessments

- Ideal for R&D, QA, and accelerated aging tests

Yes. GEN3 provides installation assistance, training, and ongoing technical support, ensuring your team can operate and interpret results confidently.

The AutoCHT has been designed to operate in the 40˚C and 80-90% RH condition. The work in the research community has selected this condition. It is suitable as the flux activators will not sublimate at 40˚C, and the high humidity makes achieving dewing conditions manageable. In principle the technique can be configured to operate under different conditions.

The AutoCHT is designed to operate with cycling conditions. Condensation cycling, forming the water film and then flashing it off, is typical of field conditions. The research community has adopted the sensible condition of 1 hour cycles, 1 hour of condensation, and 1 hour dry. The AutoCHT system is very capable of achieving this.

A condensation test in less than 1 day is possible, whereas a typical SIR test lasts a minimum of 7 days. Establishing quickly if there are intrinsic weaknesses in the test vehicle. The rapid test time has the potential to condensation testing the test method of choice. Hence, a significant proportion of traditional SIR testing may switch to condensation testing.

The AutoCHT scope of supply

AutoCHT Control

Platen: 189mm x 402mm x 168mm (H x W x D)

Liquid Connections - 8mm Tubing

12x Magnets

USB cable

AC Mains cable (appropriate to the customer’s region)

3x AutoSIR2+ Measurement Cables

The AutoCHT is fully integrated with the GEN3 AutoSIR2+ and cannot be used as a stand alone system.

We pride ourselves on the quality of our technical back-up to customers and believe that the most effective communication tool is to offer a comprehensive range of support information through our free TechShot™ service.

TechShot™ includes:

- Latest news and updates from GEN3

- A forum where you can share your questions to be answered

- Industry leading advice

- Technical articles, videos and presentations

- User manuals for troubleshooting

COMING SOON