The Importance of SIR Testing in Electronics Manufacturing

In today’s electronics manufacturing landscape, ensuring long-term reliability is non-negotiable. For companies outsourcing production, Surface Insulation Resistance (SIR) testing has become a critical safeguard against hidden risks that threaten product performance. Aligned with the updated IPC J-STD-001H standard, SIR testing provides objective evidence of electrochemical safety, making it indispensable for brands prioritising quality and compliance.

Are you wondering if SIR Testing should be conducted during your manufacturing process? The Answer is YES and here’s why!

SIR testing should be a non-negotiable requirement in your manufacturing partnerships.

SIR testing evaluates how well a printed circuit assembly (PCBA) resists electrochemical failures caused by ionic residues from fluxes, solders, or contaminants. Under IPC J-STD-001H, manufacturers must now provide objective evidence – typically via SIR testing – proving their processes leave no harmful residues that could degrade insulation resistance over time. But you may be thinking, what does that have to do with me? Well, If you aren’t asking for SIR Testing to quantify your products reliability . . . you should be!

The Hidden Costs of Skipping SIR Testing

Neglecting SIR testing shifts liability to your brand. Consider these consequences:

Field Failures - Ionic residues can cause intermittent faults or total failures, leading to warranty claims and reputational damage.

Brand Erosion - Poor performance in critical applications (e.g., medical, automotive) destroys trust.

Lost Revenue - Recalls or redesigns cost 10–100x more than preventive testing.

Here are just some of the impacts of electromechanical failures;

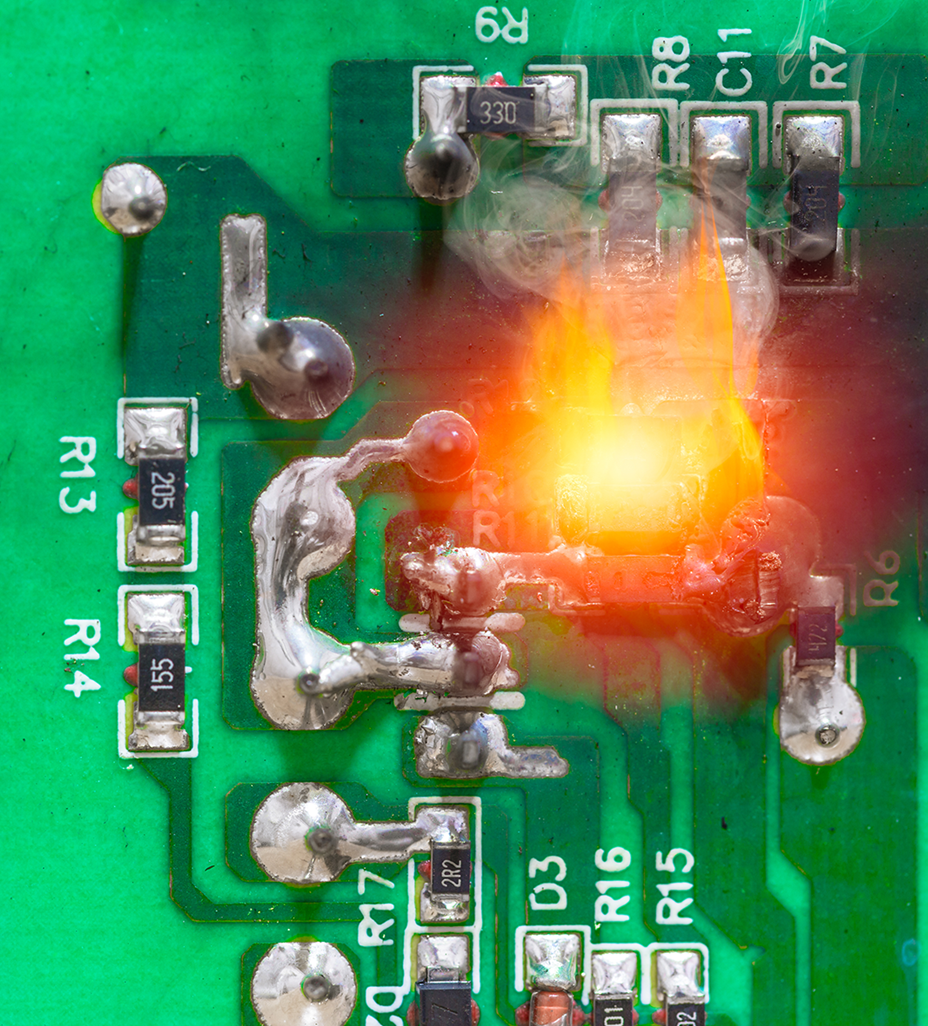

Electrical safety issues: Designers risk creating products with unsafe fluxes that can cause short circuit's on PCBs, potentially leading to production failures, machine malfunctions, or defective end devices.

- Reduced product reliability: SIR testing helps identify potential electrochemical migration and formation of conductive paths that could lead to short circuits over time. Skipping this test may result in products with shorter lifespans or unexpected failures during use.

Increased long-term costs: Early detection of weaknesses and issues through SIR testing is critical in reducing failures once the product is on the market. Without proper testing, problems may arise later in the product's life-cycle, leading to costly recalls, repairs, or replacements.

Missed optimisation opportunities: SIR testing provides valuable data and insights that enable manufacturers to make informed, data-led decisions for future product enhancements. Without this information, designers may miss opportunities to improve their products' performance and reliability.

Incompatibility issues: SIR testing helps identify potential problems when combining different materials or components. Without it, designers may unknowingly create products with incompatible elements that could lead to decreased performance or failure.

Risk Mitigation: Substandard cleaning or material changes at your manufacturer’s facility can introduce residues that cause short circuits, leakage currents, or catastrophic failures in humid or high-temperature environments.

Compliance Assurance: Without SIR test data, your products may fail to meet IPC standards, risking non-compliance penalties or recalls.

- Long-Term Reliability: SIR testing simulates years of environmental stress in days, exposing weaknesses before products reach customers.

For example, a change in conformal coating supplier at your contract manufacturer might save costs but introduce incompatible chemistries. Without SIR retesting, this could lead to latent failures in the field.

Demanding SIR testing isn’t just about compliance – it’s about owning quality control in a fragmented supply chain, SIR testing is the cheapest insurance policy you’ll ever buy.