The Essential Guide to Conformal Coating in Electronics – Importance, Challenges, and Best Practices

Conformal coating is a critical process in modern electronics manufacturing, providing a protective barrier that shields printed circuit boards (PCBs) and components from harsh environmental factors. Here we will explore why conformal coating is essential, the common issues that can arise, the steps you can take to prevent them, and the different application methods and tools required.

Why Conformal Coating is Important

Conformal coatings are thin, protective polymeric films applied to PCBs to safeguard against moisture, dust, chemicals, salt spray, and temperature extremes. This protection is vital for ensuring the reliability and longevity of your electronic devices, especially those used in demanding environments such as aerospace, automotive and medical. Utilising conformal coatings comes with a range of benefits:

- Enhanced dielectric resistance and operational integrity

- Prevention of corrosion, mould growth, and electrical failures

- Improved thermal and electrical insulation, allowing for higher voltage gradients and closer track spacing

- Reduced component failure rates and extended device lifespan, lowering maintenance and replacement costs

Despite its benefits, conformal coating can introduce defects if not properly applied or if the wrong materials or methods are used. Some of the most prevalent issues include;

- Capillary Flow: Coating migrates away from certain areas, leading to uneven coverage.

- Cracking: Fractures in the coating expose components to contaminants.

- De-Wetting: The coating beads up and fails to adhere due to surface contamination.

- Delamination: The coating lifts away from the substrate, leaving areas unprotected.

- Orange Peel: Uneven, textured finish that may indicate process flaws.

- Bubbles, Pinholes, and Foam: Air pockets reduce protective effectiveness.

These defects can compromise the coating’s protective properties, leading to premature device failures therefore it is crucial that you take the appropriate steps to prevent exposing your PCB to such Risks. A rising concern that we are beginning to see more frequently are Edge coverage issues, this is due to the tendency of coatings (like acrylic, silicone, epoxy, or urethane) to be thinner or even absent on sharp edges or corners of the component. This presents a huge reliability concern, as it compromises protection against moisture, corrosion, dust, and electrical leakage. Some of the Key Problems with Edge Coverage include:

- Thinner Coating at Edges and Corners:

- Surface tension during application and curing causes coatings to pull away from edges.

- Gravity can cause flow-off from corners during dip or spray coating.

- Inadequate Protection:

- Sharp edges are high-risk points for corrosion, arcing, or moisture ingress.

- Reduced dielectric strength at the edges can lead to insulation failure.

- Cracking or Delamination:

- Thermal cycling or mechanical stress can cause coatings to crack at thin edge areas.

- Inconsistent Thickness:

- Difficult to meet IPC standards for uniform film thickness, especially at edges.

Preventing conformal coating defects involves careful attention to process control and preparation.

Thorough Cleaning: Ensure the PCB is free from oils, flux residues, and other contaminants before coating to prevent de-wetting and delamination. This can be achieved through a number of methods, the MBtech NC25 provides a thorough and efficient way to clean your PCB’s combined with a cleaning chemistry such as Zestron and the an Ionic Contamination Tester such as the CM is a valuable process control tool.

Correct Application Thickness: Apply coatings within the manufacturer’s recommended thickness to avoid cracking, bubbles, and capillary flow.

Proper Curing: Adhere to specified cure times and temperatures to prevent cracking and ensure adhesion.

Material Compatibility: Select coatings that are compatible with both the substrate and the intended operating environment.

Process Control: Use appropriate equipment settings (e.g., air pressure for spraying) and allow adequate drying time between coats.

- SIR (Surface Insulation Resistance) Monitoring: Poor edge coverage under condensation leads to measurable drops in SIR.

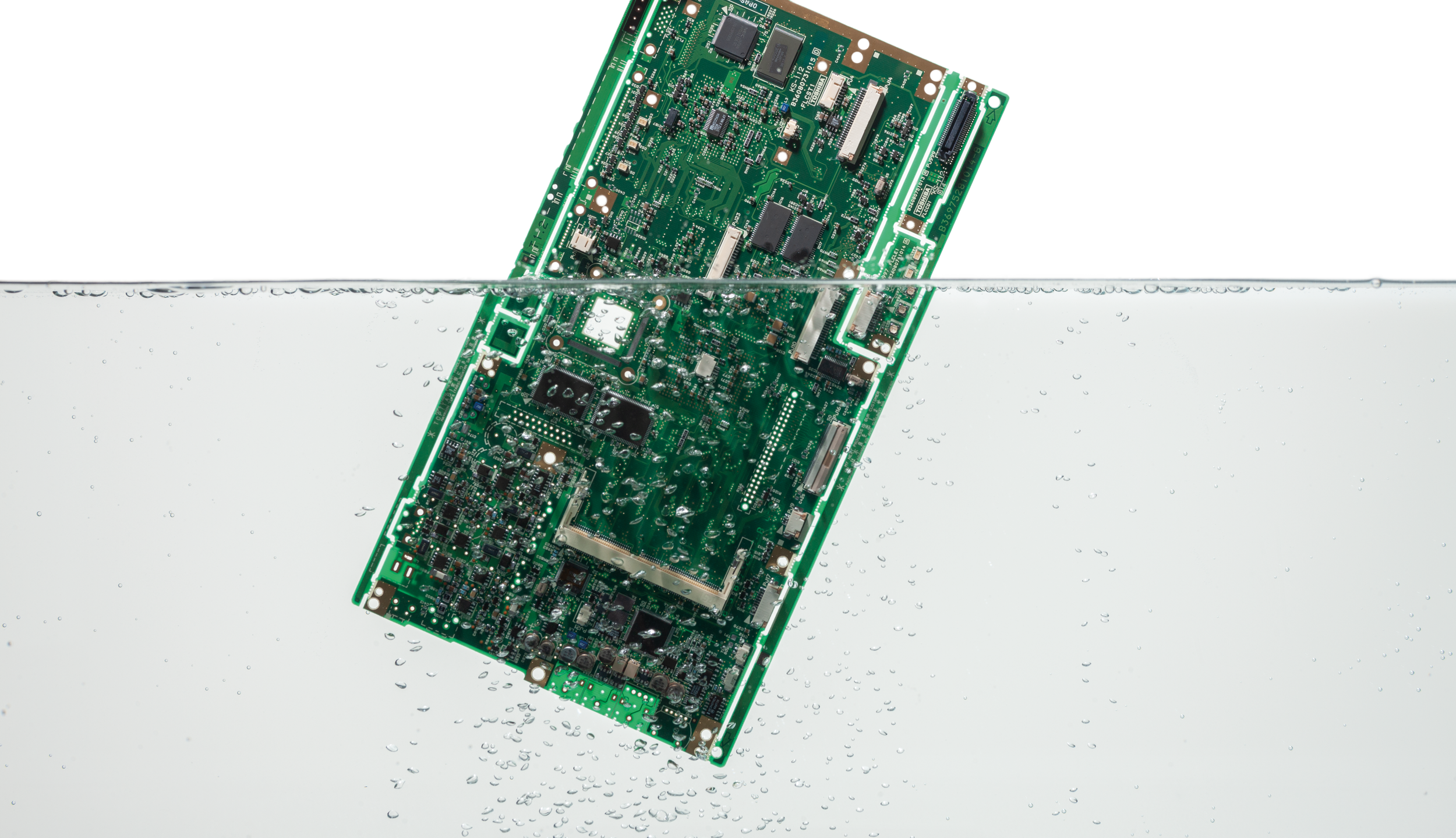

Condensation testing is revolutionary testing tool, and a critical method for identifying edge coverage weaknesses in conformal coatings by simulating harsh moisture conditions that amplify defects in a matter of hours. Condensation creates a uniform water layer across the board, penetrating even microscopic gaps at edges where coatings may be thin or absent. This exposes unprotected areas to electrochemical migration, dendritic growth, or corrosion. Furthermore condensation testing stresses coatings more aggressively than humidity alone. Geometric challenges (e.g., components with sharp edges, and specific lead configurations, and thick copper traces) exacerbate capillary action at edges, revealing weaknesses not detected in standard tests.

Methods of Conformal Application and Required Tools

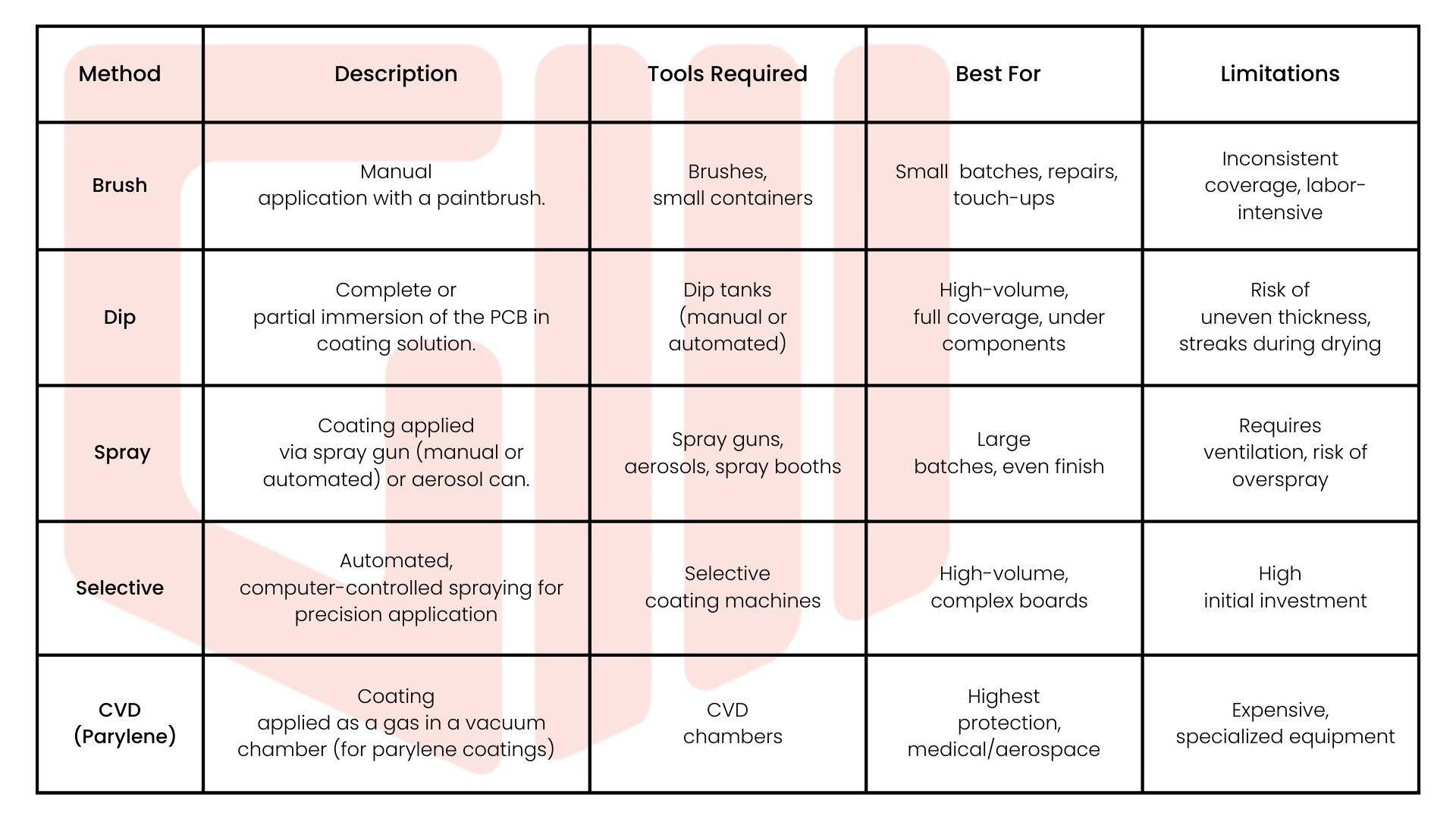

There are several methods for applying conformal coatings, each with its own advantages, limitations, and tooling requirements.

- Brush Application: Simple and cost-effective; best for small runs or rework. Achieves targeted coverage but may lack uniformity.

- Dip Coating: Efficient for coating entire assemblies, including under components. Dip coating can be manual or automated; care must be taken to control withdrawal speed and drying to avoid streaks or unevenness.

- Spray Application: Provides a uniform, high-quality finish and is well-suited for both manual and automated production. Spray application requires proper ventilation and control of spray parameters.

- Selective Coating: Uses programmable equipment for precise, repeatable application, ideal for high-volume production with complex masking requirements.

- Chemical Vapor Deposition (CVD): Used for parylene coatings, offering superior protection but requiring specialized equipment and higher cost.

Conformal coating is indispensable for protecting electronics from environmental hazards, improving reliability, and extending product life. However, achieving optimal results requires careful material selection, thorough surface preparation, and the right application method for the job. By understanding the potential pitfalls and adhering to best practices, manufacturers can ensure their electronics are well-protected and perform reliably in the field.