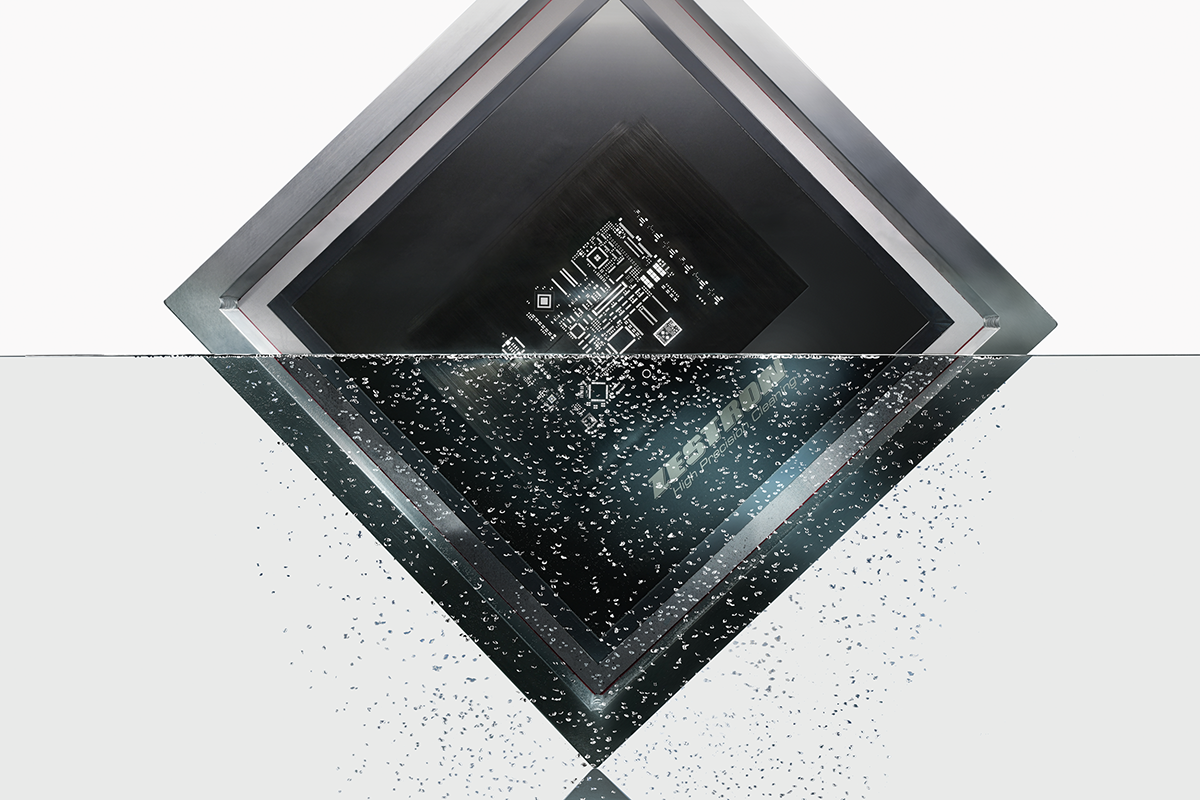

Zestron

Zestron is a global leader in the field of cleaning and contamination control solutions for the electronics industry. Specialising in providing advanced cleaning chemistries and processes that ensure the reliability and performance of electronic components.

In October 2024 GEN3 and Zestron became strategic partners, and GEN3 are now a leading supplier of Zestron chemistry and reliability services for the UK. As specialists in delivering Zestron's full range of cleaning products, GEN3 offer a free complimentary cleaning consultation tailored for various applications, including stencil cleaning, PCB cleaning, and maintenance of electronic assemblies.

GEN3 and Zestron's strategic partnership provides extensive technical support and training to help customers optimise their Manufacturing processes and improve product quality, offering a vast range of analytical test services and process implementation coaching.

- Longer bath life than conventional surfactant cleaners

- Reduced cleaner consumption

- Lower maintenance and overall costs

- Very low VOC values: particularly environmentally compatible

- Very good filterability: high economic efficiency

- Surfactant-free: no surfactant residues on surfaces

- Wide process window, therefore suitable for various cleaning applications in electronics

- Very high bath loading capacity, thus enabling very long bath service lives

- Based on halogen-free, organic solvents, therefore particularly environmentally friendly

Services

Zestron® Flux Test

Zestron® Resin Test

Zestron® Bath Analyzer 20

Zestron® Coating Layer Test

Test Services Include;

- ION Chromotography

- FTIR

- SIR Testing

- CAF Testing

- PICT

- Visual Inspection

- Scanning Electron Microscope

- Flux test/Resin Test

- Coating Layer Test

- Coating Reliability Test

Together GEN3 and Zestron checks your entire cleaning process using a wide variety of optical, chemical or physical - test methods. In addition, we can provide you with comprehensive technical reports, including picture evidence, to ensure total traceability.

Visit the Zestron Academy

Looking for the perfect cleaning chemistry for your application?

Answer our simple questionnaire and a member of the GEN3 team will be in touch with the solution for you!

Yes, although we list a limited range of products on our website, GEN3 stock and supply the full Zestron product range. Please submit and enquiry using the contact form below, or email sales@gen3systems.com for more information.

GEN3 offers a complimentary 60-minute cleaning consultation with no obligation. During the session, you’ll receive expert guidance from both our Technical Manager and Zestron Product Manager. Together, they will review reliability testing, process control, and objective evidence to help you achieve optimal performance, regulatory compliance, and validated processes. The session helps to navigate the complexities of process validation, leaving you with actionable insights and product recommendations to support your production process.

For more information, please contact us at sales@gen3systems.com.

With over 50 years of expertise, Gen3 is renowned for its leadership in electronics reliability testing and contamination control, with a collaborative foundation in advancing industry standards and innovation. Their partnership with Zestron reinforces a unified solution for cleaning, testing, and quality assurance in electronics manufacturing—streamlining reliability under one roof.

There are several ways to check the condition of your cleaning chemistry.

Firstly there is the titration method using the Zestron Bath Analyser kits. These are a simple and cost-effective way to monitor bath concentration of both Alkaline and ph Neutral cleaning agents.

The Zestron Eye Mobile is a process monitoring tool which allows an operator to check the bath concentration and record the results. It can be programmed to monitor most Zestron cleaning agents.

The Zestron Eye is a dedicated process control tool which can be installed in most types of cleaning machines and allows real time monitoring of the cleaning process.

The video below gives a brief overview of the different methods for monitoring the condition of your cleaning process: https://www.youtube.com/watch?v=F9IZcBYIvVU

In addition, it is possible to evaluate the condition of your cleaning chemistry by sending bath samples to Zestron for analysis to help determine bath life. Please contact for sample bottle kits.