NordsonSELECT

Selective soldering is the process of selectively soldering components to printed circuit boards and moulded modules. The approach is typically chosen for processes where components could be damaged by the heat of a reflow oven in a traditional SMT (surface mount) assembly process or where reliability dictates through-hole mounting.

Selective soldering is often used in combination with a reflow process where the selective soldering is a post-process limited to select parts, therefore the selective soldering process must be sufficiently precise to avoid damaging the previously reflowed components. Entry level selective soldering is often used as an efficiency and quality improvement solution over hand soldering.

A robust selective soldering system delivering the optimum balance between flexibility, throughput and large board size. Unique features include combined fluxing, preheating and soldering for easy integration into batch or in-line production.

A robust selective soldering system delivering the optimum balance between flexibility, throughput and large board size with many unique features, including concurrent fluxing, preheating and soldering for faster processing time.

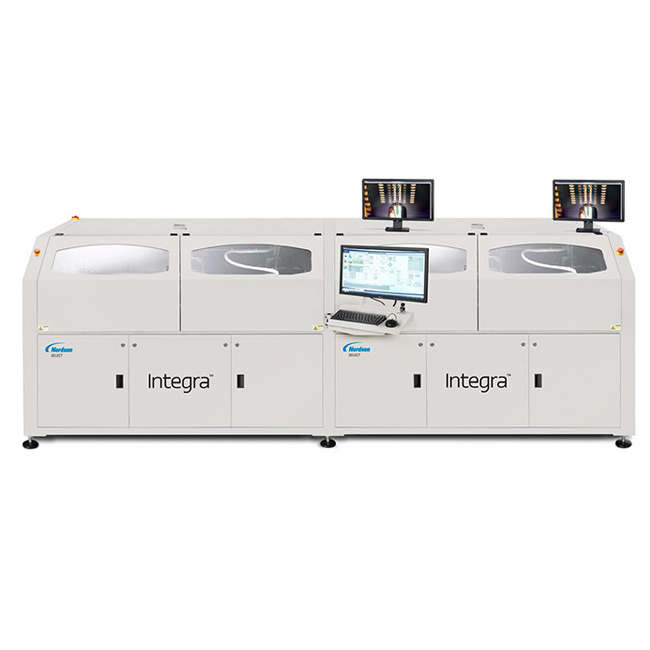

A multi-station selective soldering system designed for high-volume applications with maximum throughput. The Integra™ 508.3 has many unique features, including concurrent fluxing, preheating and soldering.

A multi-station selective soldering system designed for high-volume applications with maximum throughput. The Integra™ 508.4 has many unique features, including concurrent fluxing, preheating and soldering.

A multi-station selective soldering system designed for high-volume applications with maximum throughput. Due to its modular design, the Integra™ 508.5 can be matched to the requirements of various high-volume applications.