CM Series

The World's First Dual-Method Ionic Contamination Tester

Revolutionising electronic manufacturing quality control, the CM Contaminometer Series is a cutting-edge 6 Sigma verified system that combines traditional ROSE testing with innovative Process Ionic Contamination Testing (PICT). This game-changing device provides unprecedented precision in measuring ionic contamination on electronic circuit boards, components, and assemblies.

- New Capability to run ROSE test and PICT

- New Advanced traceability features for tracking boards and their history

- New Software featuring a new user interface for an enhanced user experience

- New Alarms for solution leakage and reduced ventilation

- New Built-in conductivity meter

- Improved automatic temperature and CO₂ compensation to remove any effects of atmospheric pollution from contamination results.

- Improved serviceability

- Improved accuracy and stability with redesigned hardware for optimum measurement capability

- The CM Series is Six-Sigma (6σ) verified as a process control tool

- The CM series has proven Gauge R&R (Repeatability and Reliability) of ~2%

- High fluid circulation rate, ensuring fast removal of ionic contaminants from PCBA whilst providing smooth, bubble-free circulation at all times

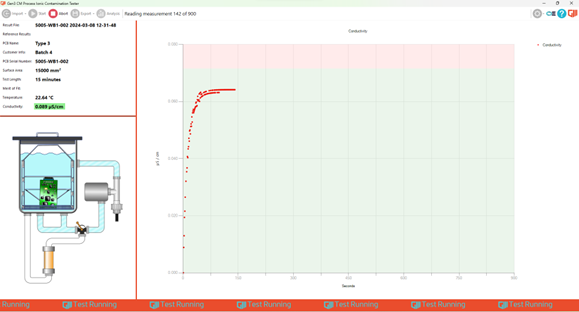

- Unique CURVE-FITTING Analysis algorithm (Merit of Fit) to predict results of longer tests

- Unique solid gold measuring cell, ballistic amplifier providing a test accuracy of <0.005μS/cm

- Complete testing cycle of only 3-minutes & full regeneration in typically < 6 minutes

D: 35mm

H: 330mm

D: 33mm

H: 480mm

D: 33mm

H: 590mm

D: 63mm

H: 480mm

D: 33mm

H: 625mm

D: 7mm

Download the latest software for the CM Ionic Contamination Test System. Serial number registration required.

The CM Series includes a range of tools and accessories that fully equip the user with all necessary items to perform Contamination Testing (all included as standard with the system). All tools can be ordered on an individual basis, and can be retro-fitted to our original CM Series.

Within our comprehensive Accessories Kit:

- Thermometer

- Cleaning Brush

- Fluid Dispenser

- ESD Wrist Strap

- Steel Ruler

- Claw Pick-up Tool

- CM Software USB Stick

- Fluid Draining Tool

Our range of PCB and Component Handling Frames are an effective tool in providing quick and reliable insertion, drainage and removal of boards from the Test chamber during the testing procedure.

They compromise an Electropolished Stainless Steel frame that includes wire supports for larger boards and a mesh basket for smaller boards and components.

Rotating draining arms allow the frame to rest on the tank edge once testing is complete so that the test solution can drain off of the test piece and back into the test chamber.

We pride ourselves on the quality of our technical back-up to customers and believe that the most effective communication tool is to offer a comprehensive range of support information through our free TechShot™ service.

TechShot™ includes:

- Latest news and updates from GEN3

- A forum where you can share your questions to be answered

- Industry leading advice

- Technical articles, videos and presentations

- User manuals for troubleshooting

COMING SOON

Ionic contamination refers to the presence of unwanted ionic residues on the surface of materials, particularly in industries like electronics, semiconductor manufacturing, and medical devices. These contaminants typically arise from flux residues, soldering processes, human handling, or environmental exposure. Ionic contamination poses significant risks to electronics manufacturers, affecting product reliability, performance, and longevity.

Used to detect ionic residues that remain following the manufacturing Process. It's important to test for ionic contamination because it can: Impact conductivity, cause corrosion, Lead to electromechanical migration, cause parasitic leakages, and complications during PCB rework.

PICT offers several advantages over the traditional ROSE (Resistivity of Solvent Extract) test. Unlike ROSE, which attempts to measure total residues, PICT focuses on reproducibly removing and measuring a consistent amount of residues. This approach is more suitable for monitoring changes in the manufacturing process. While PICT and ROSE tests are similar in many aspects, PICT's focus on process control and reproducibility makes it a more effective tool for monitoring and improving PCB manufacturing processes.

The CM best suited to your application depends on your board size, and PCB surface area. Ensure your PCB is no larger than the maximum PCB size of your desired CM Series, if the surface area is smaller than the minimum surface area (found HERE) you can add additional boards to increase the surface area in the tank.

We recommend that you use a number of test pieces in one test to bring the area above the minimum level.

Prior to running any PCB tests, run 2-3 five-minute tests with no PCB’s in the tank to remove any contamination from the test solution and air bubbles from the pipes.

On the back on the bottom right hand corner.

To acceptably measure the conductivity of a liquid certain tolerances must be made to allow for variations whilst in operation. For this reason, it is essential that tests be performed within the range of 24 ºC and 30 ºC.

It is essential that only Analar, Reagent grade fluids are used. This applies to the Deionised water, alcohol (Propn-2-Ol), Sodium (N), Chloride (Cl)

Ratio of specimen to test solution is 10 ml/cm2. A volume of test solution different to 10ml/cm2 will greatly reduce the system sensitivity and therefore produce either False Positives or False Negatives.

The maximum test duration shall be <15 minutes. This is to avoid “leaching effects” caused by the aggressive condition of the de-ionised solution. Of course the ratio is perpetually subject to variation due to one, some or all of the above.